Meter stick

The simplest way to measure length is to use an ordinary meter stick. In the laboratory, our meter sticks are carefully calibrated in centimeters with a millimeter least count. That is, the millimeter is the smallest subdivision on the meter stick, which can be seen in Figure 1. This means the millimeter is the unit of the smallest reading that can be made without estimating

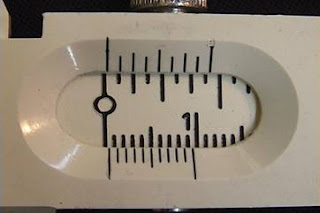

Figire 1 This meter stick is caliberated in centimeters

A measurement reading usually has one more significant figure than the least count reading of the scale. The least count of our laboratory meter sticks is 0.1cm and therefore a reading can be made to 0.01cm. Figure 2 above shows a meter stick being used to measure the length of a plastic strip. The meter stick is calibrated in centimeters, so we know that the strip is between 41 and 42 cm. The least count of this meter stick is one millimeter, so we know with absolute certainty that the object is between 41.6 cm and 41.7 cm. We then estimate the object's length to the fractional part (doubtful figure) of the least count subdivision. In Figure 2, it we may estimate that the strip is closer to 41.6 cm than it is to 41.7 cm and report the length to be 41.64 cm or 0.4164 m.

A vernier caliper (or vernier), shown in Figure 3, is a common tool used in laboratories and industries to accurately determine the fraction part of the least count division. The vernier is convenient when measuring the length of an object, the outer diameter (OD) of a round or cylindrical object, the inner diameter (ID) of a pipe, and the depth of a hole.

Figure 3. The vernier is a common instrument used to measure length, depth, and diameter

When using a meter stick to measure length, for example, it is necessary to estimate the measurement's final digit (tenths of a millimeter). From the above example, the object's length was determined to be 0.4164 m, but the final digit of that measurement is doubtful since that digit was estimated. Unlike a meter stick, the vernier caliper allows the fractional part of the smallest division to be accurately determined, not merely estimated.

The vernier consists of a main scale engraved on a fixed ruler and an auxiliary scale engraved on a moveable jaw (see Figure 3). The moveable jaw is free to slide along the length of the fixed ruler. The main scale is calibrated in centimeters with the smallest division in millimeters. The moveable auxiliary scale has 10 divisions that cover the same distance as 9 divisions on the main scale. Therefore, the length of the auxiliary scale is 9 mm. When the vernier is closed and properly zeroed (see Figure 4), the first mark (zero) on the main scale is aligned with the first mark on the auxiliary scale. The last mark on the auxiliary scale will then coincide with the 9-mm mark on the main scale.

A reading is made by closing the jaws on the object to be measured. Make a note of where the first mark on the auxiliary scale falls on the main scale. In Figure 5, we see that the object's length is between 1.2 cm and 1.3 cm because the first auxiliary mark is between these two values on the main scale. The last digit (tenths of a millimeter) is found by noting which line on the auxiliary scale coincides with a mark on the main scale. In our example, the last digit is 3 because the third auxiliary mark lines up with a mark on the main scale. Therefore, the length of the object is 1.23 cm.

Figure 4. With the jaws closed, this is what a properly zeroed vernier caliper should look like. Click on the image to enlarge it.

Figure 5. An example of a vernier reading. The object's length is measured to be 1.23 cm. Click on the image to enlarge it.

Care must be taken to insure that the vernier caliper is properly zeroed (see Figure 4). (With misuse, it is possible that the vernier will not read zero when the jaws are closed, thus leading to systematic errors.) The vernier in Figure 6 is improperly zeroed. To correct this, a zero correction must be made. A correction may be either positive or negative. If the first mark on the auxiliary scale lies to the right of the main scale, then the reading is too large and the error is positive. The zero reading in Figure 6 is +0.05 cm and should be subtracted from any measurement reading. Similarly, if the first mark on the auxiliary scale lies to the left of the main scale zero-mark, then the error is negative and the correction should be added from the measurement reading.

Figure 6. An improperly zeroed caliper. In this case, the error is positive (+0.05 cm) and is to be subtracted from the measurement reading. Click on the image to enlarge it.

Reading a Tape measure

I need information on how to read a tape measure. It's my understanding the black diamond on the top scale starting at 19.2 inches is for truss layouts for 8-foot sheet goods. Is this true? Was it originally used in metric layouts? How are they used today for truss layout with 8-foot sheet goods? Could you help me out by giving an example please?

Here's some info that might be helpful:

A tape measure blade is marked both in inches and in feet. The end hook always appears to be loose and this is intentional. It's designed to slide a distance equal to its own thickness so both inside and outside measurements will be accurate. The upper scale is in 1/16-inch increments, so it reads 1/16, 1/8, 3/16, 1/4, 5/16, 3/8, 7/16, 1/2, 9/16, 5/8, 11/16, 3/4, 13/16, 7/8, 15/16, and 1-inch. The bottom scale reads in 1/16-inch increments as well, so it reads 1/16, 1/8, 3/16-inch, and so on. Studs read out at 16-inch on center, and are normally marked in red. Trusses or floor joists read out at 2-foot on center and are normally marked in black.

The black diamond on the top scale starting at 19.2 inches is for truss layouts for 8-foot sheet goods—also referred to as the "black truss" markings. Originally the 19.2 was used in metric layouts. If you divide five into 96 inches (8 feet), it will give 19.2 inches—in other words, 5 trusses per sheet.

On the other hand, the "red stud" marking every 16 inches allows for a standard layout of six studs per 8-foot (96") section. Look at it this way: there are 5 black diamonds or 6 stud markings in an 8-foot width.

Truss Example:

Count the black diamonds and notice that the fifth one lands on 8 feet. Since an 8-foot sheet spans half the distance of its size, then the second course would start at the halfway point (4 feet) or, in this case, at the third diamond, which is slightly over 3' 2 3/8". The 19.2 black truss marking is just a better span if you don't want to span 24 inches on center with today's undersized plywood. However, I prefer 16-inch on center for truss layout—especially if 1/2" wallboard will be attached to the bottom cord of trusses. Even with 19.2 layout, I would recommend using 5/8" or 3/4" plywood and 5/8" wallboard.

Micrometer

Reading an inch-system micrometer

Micrometer thimble showing 0.276 inch

The spindle of an inch-system micrometer has 40 threads per inch, so that one turn moves the spindle axially 0.025 inch (1 ÷ 40 = 0.025), equal to the distance between two graduations on the frame. The 25 graduations on the thimble allow the 0.025 inch to be further divided, so that turning the thimble through one division moves the spindle axially 0.001 inch (0.025 ÷ 25 = 0.001). To read a micrometer, count the number of whole divisions that are visible on the scale of the frame, multiply this number by 25 (the number of thousandths of an inch that each division represents) and add to the product the number of that division on the thimble which coincides with the axial zero line on the frame. The result will be the diameter expressed in thousandths of an inch. As the numbers 1, 2, 3, etc., appear below every fourth sub-division on the frame, indicating hundreds of thousandths, the reading can easily be taken mentally.

Suppose the thimble were screwed out so that graduation 2, and three additional sub-divisions, were visible (as shown in the image), and that graduation 1 on the thimble coincided with the axial line on the frame. The reading then would be .2000 +0.075

Reading a metric micrometer

Micrometer thimble reading 5.78mm

The spindle of an ordinary metric micrometer has 2 threads per millimetre, and thus one complete revolution moves the spindle through a distance of 0.5 millimetre. The longitudinal line on the frame is graduated with 1 millimetre divisions and 0.5 millimetre subdivisions. The thimble has 50 graduations, each being 0.01 millimetre (one-hundredth of a millimetre). To read a metric micrometer, note the number of millimetre divisions visible on the scale of the sleeve, and add the total to the particular division on the thimble which coincides with the axial line on the sleeve.

Suppose that the thimble were screwed out so that graduation 5, and one additional 0.5 subdivision were visible (as shown in the image), and that graduation 28 on the thimble coincided with the axial line on the sleeve. The reading then would be 5.00 +0.5 +0.28 = 5.78 mm.

Reading a vernier micrometer

Micrometer sleeve (with vernier) reading 5.783mm

Metric micrometers of this type are read as follows: First determine the number of whole millimetres (if any) and the number of hundredths of a millimetre, as with an ordinary micrometer, and then find a line on the sleeve vernier scale which exactly coincides with one on the thimble. The number of this coinciding vernier line represents the number of thousandths of a millimetre to be added to the reading already obtained.

Thus, for example, a measurement of 5.783 millimetres would be obtained by reading 5.5 millimetres on the sleeve, and then adding 0.28 millimetre as determined by the thimble. The vernier would then be used to read the 0.003 (as shown in the image).

Inch micrometers are read in a similar fashion.

Note: 0.01 millimetre = 0.000393 inch, and 0.002 millimetre = 0.000078 inch (78 millionths) or alternately, 0.0001 inch = 0.00254 millimetres. Therefore, metric micrometers provide smaller measuring increments than comparable inch unit micrometers—the smallest graduation of an ordinary inch reading micrometer is 0.001 inch; the vernier type has graduations down to 0.0001 inch (0.00254 mm). When using either a metric or inch micrometer, without a vernier, smaller readings than those graduated may of course be obtained by visual interpolation between graduations.

Micrometer Parts

Additional reading Metric Micrometer